5S Tool Control Solutions

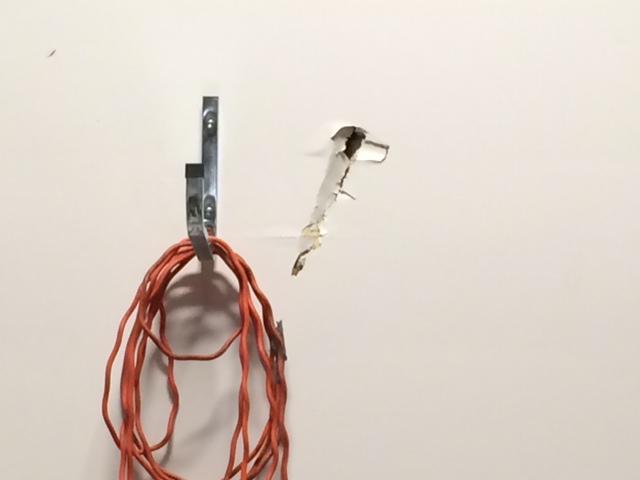

Today while touring a manufacturing facility I was shown the below image. It’s a great example of the need for tool control solutions. As the story goes, the President of the company was looking for a tool in the cluttered Tool Shop area.

After searching for quite some time, he eventually found the tool he was looking for only to discover it was broken. In his frustration, he whipped it across the room resulting in the tool shadow you see below. The tool is still stuck in the wall. We laughed about the incident and I had to admit I’d never seen tool shadows created in that manner. Not quite the tool control solutions that we advise.

As we laughed, we also realized the seriousness of the situation. We discussed the likelihood that his workforce runs into similar situations daily. How many labor hours do they waste day in-day out in the search for tools or information to complete a job?

This is a great case study for the need for 5S and tool control solutions. If the tools in that room were Set in Order, the President would have immediately found the tool he was looking for and it would have been in working order.

Tool Control Solution: Use Shadow Boards to Hold Your Employees Accountable

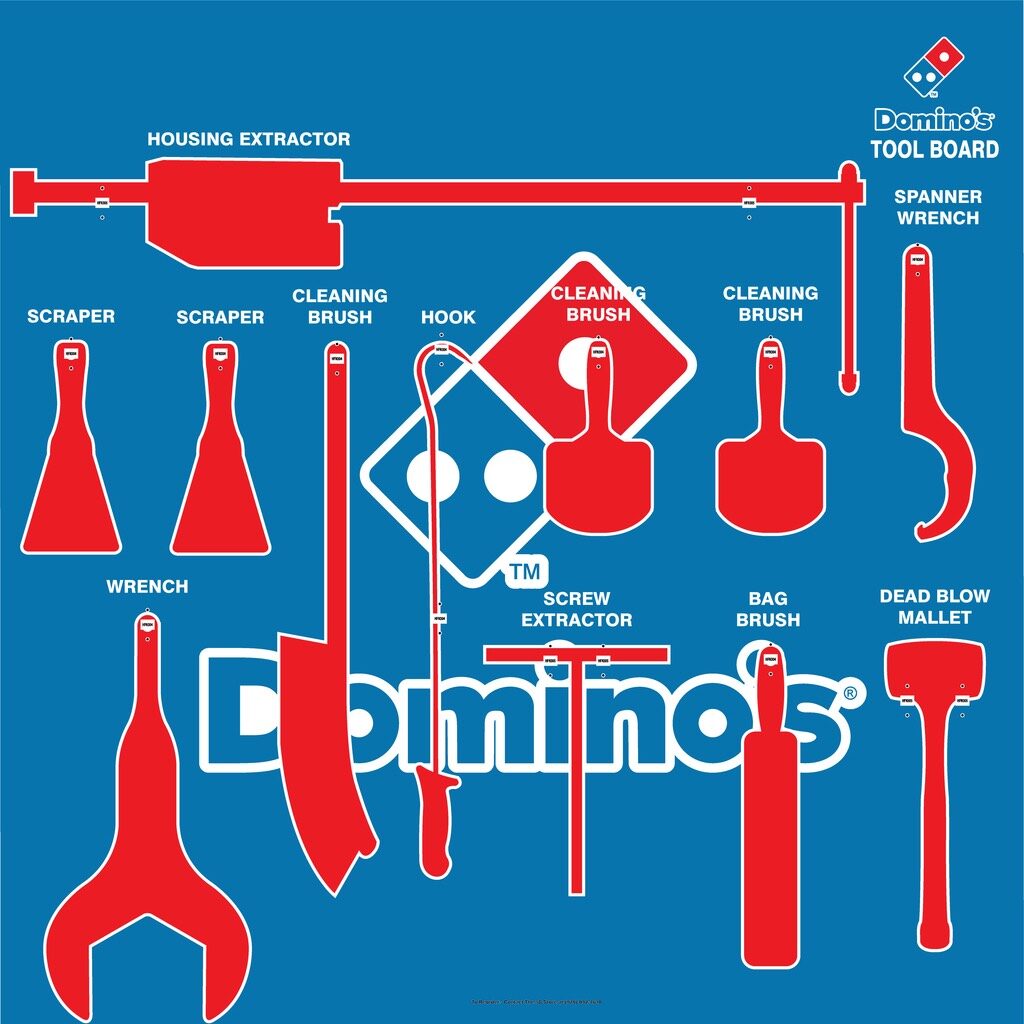

An organized tool shadow board like this will not only keep your frequently used items organized, it will prevent wasted time searching for them AND hold your employees accountable for putting them back.

Workers spend nearly 25% of their time searching for tools, information or equipment.

Having tool control solutions, the tool you need, when you need it, can significantly reduce wasted time and effort. Tool shadow boards make it easy for workers to remember where things go, and serve as a visual reminder when things haven’t been put away.

Three reasons you should be using tool shadow boards in your 5S process:

1. Save time: Workers don’t waste time searching for items needed for a task.

2. Reduce safety hazards: Tools aren’t lying around, potentially causing injury.

3. Reduce costs: Fewer tools go missing or become damaged.

CLEANING STATION TOOL SHADOW BOARDS

Our cleaning station tool boards are ideal for non-food contact or general maintenance. In our store, we offer boards made from a variety of materials, including those ideal for indoor/outdoor applications and boards that can withstand harsh chemical environments.

- Order cleaning tool boards only or as a kit with the 5 most popular general maintenance cleaning tools

- You choose board color (blue, green, red, yellow, white) and tool shadow color (black or white)

- Zinc-plated hook hardware for cleaning tools is included

CUSTOM WALL MOUNT & MOBILE TOOL SHADOW BOARDS

Custom Store-Boards are the easy solution for creating a visual system for your tools. We are ready to assist you in creating the perfect shadow boards to meet your requirements.

- Available in 4 material types

- Select from mobile, wall mount or cabinet styles

- Have your tools and supplies arranged the way you want

- Add your company branding and messaging

- Size for your specific application

Tool Control Solutions Outside of Manufacturing

Tool shadow boards are not just for the manufacturing industry. If you work in the food industry and don’t have a Tool Shadow Board, you’re missing out! Chances are you’re wasting time and money.

The power of high-quality tool control boards

I was talking to a Lean Practitioner the other day. We were discussing the attractive, high-quality tool control boards and tool shadow drawers sold at The 5S Store. During our conversation, he said that having a well designed, attractive board with the company logo and tool names on it missed the point.

I asked what point is that?

He said:

“Having them made from an outside source removed the opportunity for the shop-floor worker to design and make the board himself.” He continued, “there’s no need for it to be pretty, it just needs to be functional.”

While I understand his point to an extent. So, I reiterated that…

“The shop floor worker was involved. He laid out the tools, determined the size needed and even worked with our custom design team to create a cool layout that he was proud of.”

In fact, when it arrived, his co-workers congratulated him on designing such a cool tool board that would make the work area even nicer looking.

Functionality is the key. But is there anything wrong with it looking good as well?

Moreover, I’d suggest that having them made by an outside source can help improve the standardization of the boards. As we all know, this is the fourth, S – Standardize.