Save Employee Lives: Embrace Lockout Tags

Machines play a big part in your business. That’s not a bad thing. Machines help us do our work faster, more efficiently and more affordably than we ever could before. But, those machines can be dangerous and even deadly.

In 2020, a worker in Houston, Texas, was repairing a baler when someone decided to use the machine. Without knowing that the worker was repairing the machine, the employee turned it on. The result was a fatality.

Why didn’t that employee know that his coworker was inside the machine? How could this have been prevented?

The answer is by using a proper lockout tag as part of a Lockout/Tagout program.

What Is Lockout/Tagout?

In 1990, OSHA enacted the Control of Hazardous Energy standard, also known as “Lockout/Tagout” or LOTO. The idea is fairly simple. Any machine that is broken, being worked on, or for any other reason poses a threat if it is turned on or releases stored energy, should have a tag and lock that prohibit anyone from inadvertently engaging the machine.

Lockout refers to using a lockout device to ensure that the machine cannot be used while it is being worked on or not functioning properly. Tagout refers to the placing of a tag on the machine stating that it is not to be used until the tag is removed by the person who put it on. This prevents anyone from taking it upon themselves to try to remove the lock and fire up the machine. With proper training, lockout/tagout program procedures have been proven to reduce injuries and save lives.

Establishing an Effective Lockout/Tagout Program

The first step to protecting your employees with a LOTO program is to understand OSHA’s guidelines. Then, survey your worksite for any and all machines and situations that may require appropriate LOTO precautions. Some key situations you’ll want to look for include:

- Machines with moving parts – When someone has to enter or repair a machine with moving parts like welding heads, saws, robotic arms or similar mechanisms, those parts represent dangerous potential energy.

- Electrical repairs – Electricity is, by definition, energy. When working on electrical components, it’s essential to implement a LOTO program to ensure the worker’s safety.

- Machines with missing, clogged, or damaged parts – When a part of a machine isn’t working, it may seem easy enough to just reach in and fix it or get it loose, but without proper LOTO, that part could trigger the machine to get into motion causing injury to the worker trying to fix it.

The next is to make sure you have all of the materials you need, including the appropriate locks and lockout tags for your business. This could include padlock labels, as well as required tags.

One thing that’s easy to overlook is your lockout tags. If your first thought is, “I think we have some around here somewhere,” that’s not good enough. Consider the following:

- Do you know if you have all of the appropriate lockout tags including tags in Spanish or other languages as needed?

- Are your tags clean and in good shape? A tag that’s hard to read is not a viable option.

- Are your tags organized so you can find the one you need?

You need to know that you have the right tags and where to find them when you need them or else your lockout/tagout program simply won’t work and your employees could be put in danger.

Get Organized

Find a way to keep your tags and locks organized. Set aside one area in your workplace for safety materials. Avoid the temptation to toss all of your tags into one drawer so that when you need one you have to sift through a hoard of used, faded and irrelevant tags just to find the one you need.

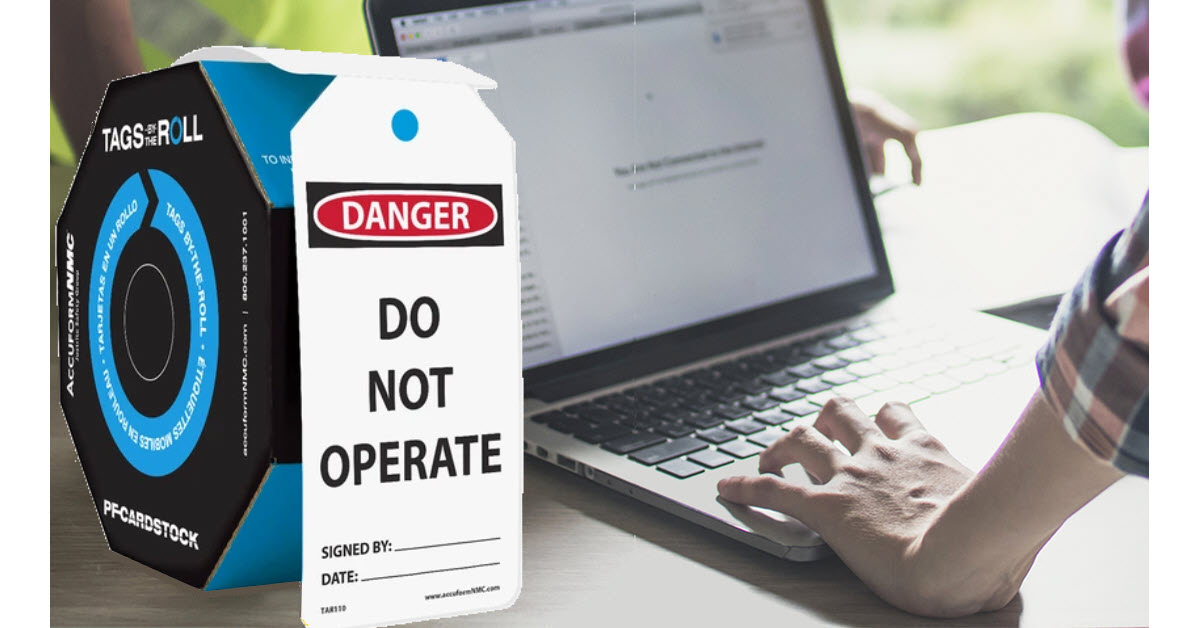

One simple solution for ensuring that you have the right tags ready and available when you need them is to order Tags by the Roll. A Tags by the Roll portable tag dispenser box contains a roll of safety tags. The dispenser box protects tags until they are needed and makes it easy for safety managers, service personnel and machine operators to transport and access tags on the job. Tags by the Roll can be stored on shelves, on a rod or carried throughout a facility on a belt or cart as part of your lockout/tagout program.

Once you determine which tags you use the most, order Tags by the Roll for each one, establish a storage area for them and set them up. You’ll never have to dig through drawers or tool boxes again hunting for the tag you need. It’s one less thing to worry about and a simple way to improve your LOTO safety program.

This Is Just the Start

Your lockout tags are just one part of an effective lockout/tagout program, but they are an essential part. Without the proper tags there is no communication and that creates a dangerous situation for your employees.

If you’re striving to minimize injuries in your workplace (and who isn’t), you owe it to yourself and your employees to get organized with your lockout tags so you know that you’ll have the tags you need, in good shape, when you need them.