5S and Color Coding for the Food Industry

5S and color coding are a natural fit for the food industry. You can create safe and clean spaces from the front doors at your place of business to the shelves in your stock department when items are in the appropriate locations and organized to find at a glance.

Why is 5S and Color-Coding Important in the Food Industry?

5S in the food industry is especially beneficial because it allows workers to cut food safety risks for consumers. With visual tool displays, you can combat cross-contamination.

5S is more than what some people call, ‘a fancy housekeeping tactic,’ – which is critical for the food industry – since clean zones are mandatory for safe production. It actually encourages continuous improvement.

With the Food Safety Modernization Act (FSMA), the most sweeping reform of our food safety laws in more than 70 years, utilizing 5S principles are even more critical to ensure food is of the best quality and safe to consume.

Additionally, per FSMA, food facilities must have a food safety plan in place that includes an analysis of hazards and risk-based preventive controls to minimize or prevent hazards. The 5S and color-coding methodology will reinforce this standard with safe behaviors, sanitized environments, and practices.

The breakdown of 5S Practices for the food industry:

- Sort – This is the process to remove everything that is not needed in the area. Search for everything that isn’t frequently used or needed in the immediate area and move it out. Go through every nook and cranny in the area. Label or put red tags on items that need to be moved or thrown out. This is the easiest way to sort.

- Set in Order – This is the step that generally takes the longest but is the most impactful. The goal is to increase efficiency in the work environment. Cut the chances for cross-contamination between raw and finish products with the organization. Organizing items logically together with like items prevents food-contact with non-food-contact items. Incorporating color-coded tools and visual boards will keep the appropriate zones separated.

- Shine – At this step tools, machinery, and the work area should be completely cleaned. Provide an atmosphere where your workers can use cleaning as a way to inspect the 5S process. Keeping the area thoroughly cleaned and sanitized helps prevent the spread of fool illness and contamination – especially when cross-contaminated with cooked and raw meat can occur.

- Standardize – With this step, you can set clear, visible methods for how the area should situate. Take notes of what works and what doesn’t. Conduct a 5S audit to find solutions for inconsistent or inefficient processes or steps. With everyone in the business working toward the same goal – continuous improvement and sanitized work environments –the process should start to feel natural.

- Sustain – Conduct daily checks to ensure the above steps are routinely followed through. Sustain requires repetition, diligence, and accountability until it becomes a daily habit that’s embedded in the culture.

Color Coded Tools for the Food Industry

|  |  |  |

Why color code as part of 5S?

- It helps to prevent cross-contamination between areas, i.e. food contact areas from non-food contact areas, raw from cooked, allergen products from non-allergen products, restrooms from a production area.

- Reduces cleaning tools migrating from one zone to another.

- Reduces training time because it is easily understood by workers.

- Ship safer products.

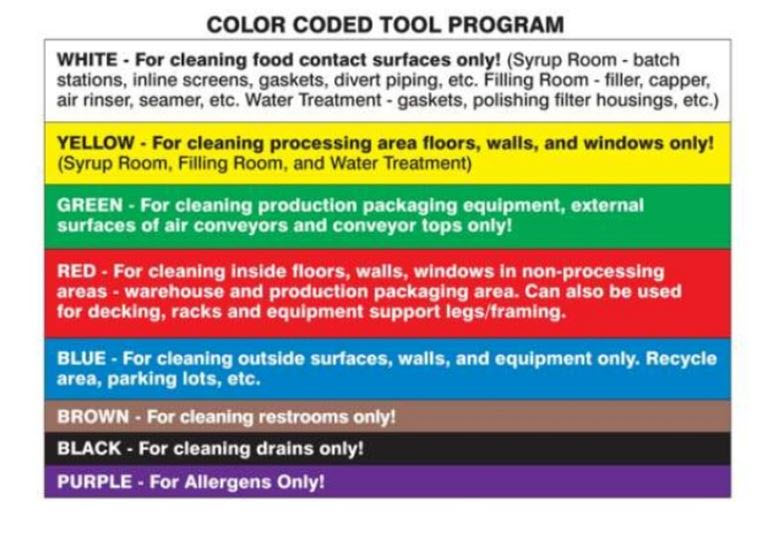

Some 5S Color Code Samples for the Food Industry:

WHITE = Food Contact Surfaces

BLUE = Non-Food Contact Surfaces

RED = Sanitation

ORANGE = Allergen Line

YELLOW = Restrooms

GREEN = Maintenance

GRAY = Waste or Trash

BLACK = Floor Drains

Browse color-coded cleaning tools.

With 5S principles utilized in your food processing plant – you keep the integrity of your brand, the quality of your product, and the health and safety of others at the top of your mission.