Safety Tip: Lockout / Tagout Procedures

The OSHA standard for The Control of Hazardous Energy (Lockout/Tagout), Title 29 Code of Federal Regulations (CFR) Part 1910.147, outlines practices and procedures to disable machinery or equipment, thereby preventing the release of hazardous energy while employees perform servicing and maintenance activities. These tips on lockout / tagout procedures will help keep your workers safe and in compliance with LOTO standards.

Lockout/Tagout procedures apply in these circumstances:

- While servicing or maintaining equipment, when unexpected startup of the machine or release of stored energy could occur

- During normal production when workers must remove or bypass a guard or safety device

- During normal production when workers place any part of their body into the danger zone or near the machine’s point of operation

- During all setup activities

3 Key LOTO Steps

NIOSH recommends that workers follow the regulations contained in their employer’s hazardous energy control program and complete all employer-provided training on hazardous energy control procedures.

Before beginning machine adjustment, maintenance, or servicing work, always do the following:

1. De-energize all sources of hazardous energy:

- Disconnect or shut down engines or motors.

- De-energize electrical circuits.

- Block fluid (gas or liquid) flow in hydraulic or pneumatic systems.

- Block machine parts against motion.

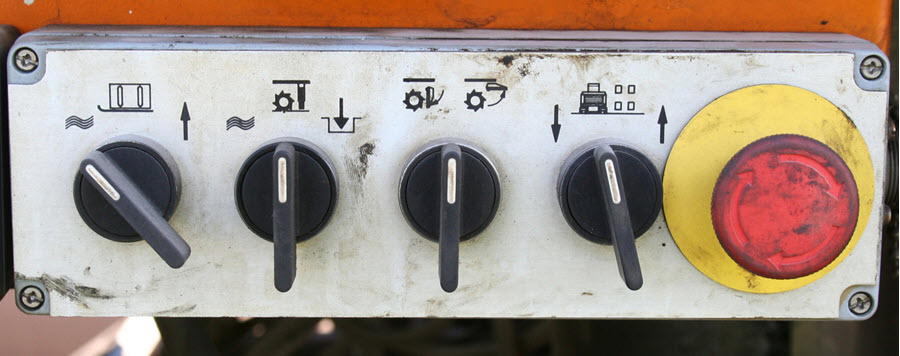

2. Lockout and tagout all forms of hazardous energy:

- Electrical breaker panels

- Control valves

- Any other form

3. Block or dissipate stored energy:

- Discharge capacitors.

- Release or block springs that are under compression or tension.

- Vent fluids from pressure vessels, tanks, or accumulators, but never vent toxic, flammable, or explosive substances directly into the atmosphere.

- Make sure that only one key exists for each of your assigned locks and that only you hold that key.

- Verify by test and/or observation that all energy sources are de-energized.

- Inspect repair work before removing your lock and activating the equipment.

- Make sure that only you remove your assigned lock.

- Make sure all workers are clear of danger points before re-energizing the system.

Lockout / Tagout Resources:

- Review Title 29 Code of Federal Regulations (CFR) Part 1910.147 here.

- Visit the OSHA LOTO Tutorial page.

- Visit the main OSHA LOTO site.

- Read our post on Key Components of a Lockout / Tagout Program.

- Select LOTO and Safety Tags at ComplianceSigns.com.