Chemical Safety Requirements for the Workplace

Did you know that everyday cleaners contain chemicals? They sure do. Simply, unknowingly mixing together chemicals can create a deadly hazardous combination.

Every hazardous chemical in the workplace matters. Regardless of how many employees work at your company or how large it is, chemical safety in the workplace is serious business.

About 32 million workers work with and are potentially exposed to one or more chemical hazards, per OSHA. There are an estimated 650,000 existing chemical products, and hundreds of new ones being introduced annually. This poses a serious problem for exposed workers and their employers.

The way chemicals are used, stored, labeled, and disposed of covers a large landscape. Chemicals and toxic substances pose a wide range of health hazards (such as irritation, sensitization, and carcinogenicity) and physical hazards (such as flammability, corrosion, and explosibility).

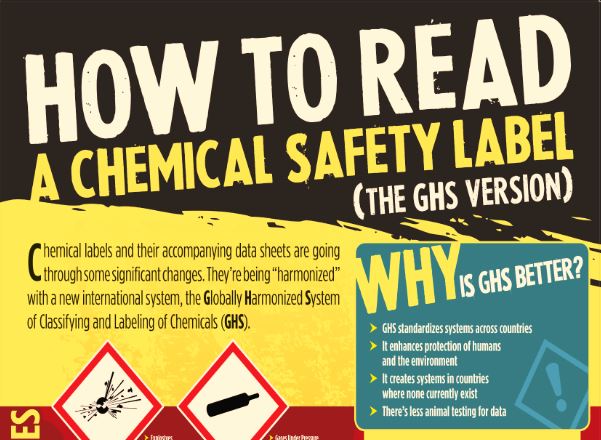

As you can see, chemical safety is important. Information about hazardous chemicals must be available and understandable to workers. Hazard Communication Posters help inform workers about chemicals and how to read the labels.

To protect workers, OSHA’s Hazard Communication Standard (HCS) requires the development and distribution of information:

- Chemical manufacturers and importers are required to test the hazards of the chemicals they produce or import and prepare labels and safety data sheets (SDS) to convey the hazard information to their downstream customers.

- All employers with hazardous chemicals in their workplaces must have labels and SDS. Exposed workers will need training for handling the chemicals. Training should include information on the hazards of the chemicals in their work area and protective measures.

With a written hazard communication program, you can ensure all employers receive the information they need for safety.

When chemicals are used in your workplace, as the employer, you are responsible for hazardous chemical safety steps, including but not limited to:

- Develop, implement, and maintain a written, comprehensive hazard communication program. This should include provisions for container labeling, collection, and availability of material safety data sheets, and a training program.

- Contain a list of the hazardous chemicals.

- Hazards associated with chemicals must be labeled.

- All covered employers must have a written hazard communication program to get hazardous information to their employees through the proper labels on containers, SDS, and training.

- Label containers with the identity of hazardous chemicals contained. Additionally, show hazard warnings appropriate for employee protection. The hazard warning can be any type of message, words, pictures, or symbols that provide at least general information regarding the hazards of the chemical(s) in the container and the targeted organs affected, if applicable. Labels must be legible, in English (plus other languages, if desired), and displayed.

Ensure all your employees can identify hazards in the workplace by providing the proper chemical safety training, hazardous communication and GHS labels and signs in the workplace.