5S As A Cultural Enabler

This is a guest article written by Scott Gauvin of Macresco

At its best Lean can be a powerful catalyst for cultural transformation.

In the short term, its implementation can change the way teams interact and how they create and deliver value to the customer and each other.

In the midterm, new processes beget new routines that together engender behavior change.

Over time, if the Lean effort is sustained, that behavior change gives rise to the fabled continuous improvement mindset that can power high performing organizations long term.

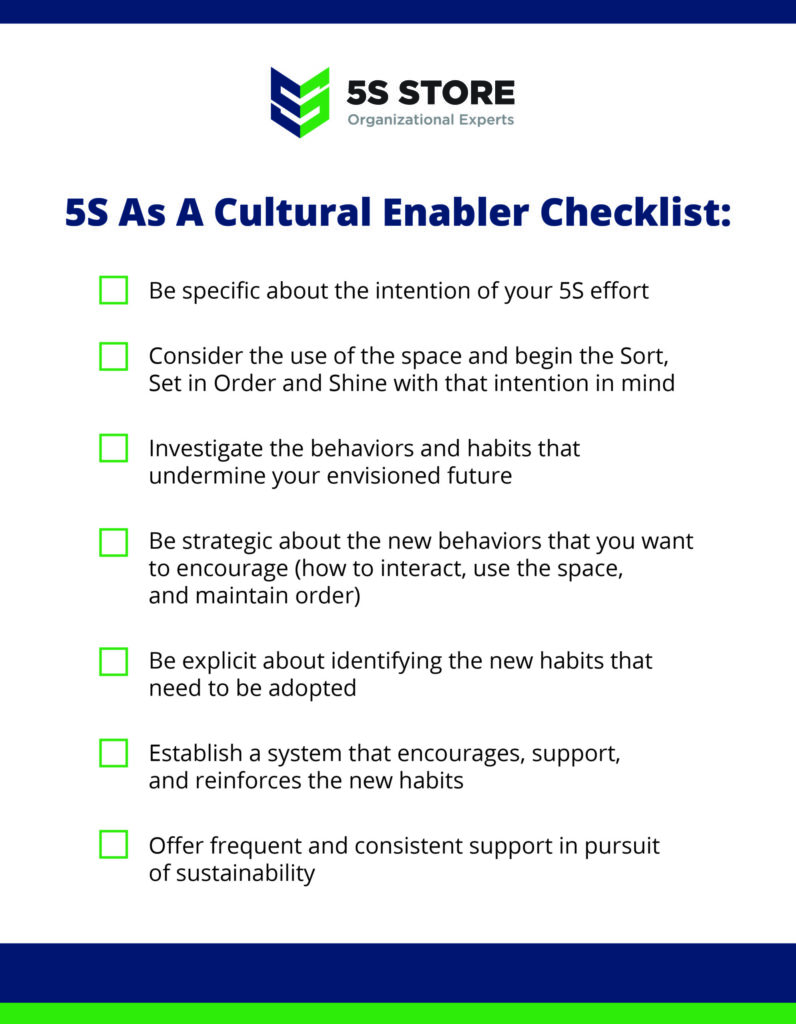

Getting from zero to the mindset shift necessary to create a new cultural paradigm requires being specific about your intention for Lean.

Your intention directly correlates with the new behaviors that will result in implementation. Organizations’ intentions for Lean are too often shaped by nearsighted needs:

- Cost savings,

- Productivity gains,

- Delivery times.

The problem with this approach is that nearsighted intention builds behavioral habits that only serve the short term.

The true value of Lean is in how it can affect the big picture. With the right intention, it is possible to have a broad lasting impact, even when you’re starting small. 5S is a great example of how a smaller-scale effort can have either a limited physical impact or serve as an important cultural enabler depending on the intention behind its implementation.

For example, 5S is traditionally executed to get a quick win and show progress when launching a Lean effort. If the intention is simply to achieve a spruced-up working environment, you’ll attain that. You may or may not be able to sustain the cleanliness depending on how you stay on top of it, but regardless, a tidier workspace in one area won’t render new thinking and new productivity and collaboration improving 5S habits in another.

If, however, you introduce 5S habits with the intention of it being the first step to improve employee engagement and company culture, Sort, Set in Order and Shine take on a new, more significant meaning with very different criteria around their implementation.

Suddenly participants aren’t just sorting to see what they have, they’re thinking about how those items got there, why they have them, why they need them, who cares about them being there, what leadership or other team members have to do with the current chaos and what can be done about it.

What kinds of 5S habits do we want to create? A habit of putting things back where they go? Or a habit of thinking critically about what creates value and what doesn’t?

Intention also plays in sustainability. Before I begin a 5S workshop I spend time trying to understand why people are working in their environments the way they are. All behavior is an expression of a need unmet – we all do what we do as a result of a need we have that isn’t being satisfied. There are tangible reasons why the area is the way it is. This is why cleaning up an environment without addressing the root causes of the current state doesn’t lead to sustainable change. It’s why we see 5S efforts repeated several times – and why my garage never stays clean.

Whatever your intention is for 5S, partnering with employees, and leveraging their experience, knowledge, and wisdom are key to seeing it come to fruition. They play an important role in helping to flag unproductive habits and identifying new ones that will sustain the change.

Declare your intentions and articulate the desired habits. Then, your role as a leader is to monitor, follow up, coach, and support those new habits – on a frequent and consistent basis. It takes 20 days to make the habit a routine and 66 days to become unconscious – this is why being strategic about the specific habits we want to create at the outset is so important.

5S habits doesn’t end when the area is clean.

Once the initial habits have become routine, it’s time to reevaluate and identify the next habits that will further the intention of the effort, work to establish those habits, and so on and so on.

For example, in my practice of using Lean to cultivate high performing organizations, reinforcement of 5S gains takes shape via a Gemba Card reminder structure. I’ve found that participation in monthly audit and scoring systems tends to be forced and is perceived as punitive. Without a guide to gauge progress though, leaders can fumble the opportunity to glean valuable insight and ask questions that are too broad or that don’t support the advancement of their effort.

The Gemba Card tool enables leaders, managers, and supervisors to have more thoughtful interaction in the Gemba than if their goal was simply to ensure that certain activities were executed or not. Here again, intention makes its mark, resulting in a higher level of engagement, improved communication, better accountability, and a higher percentage of habits becoming internalized. We also tend to see a lot less resistance to future change efforts.

Meet Scott Gauvin

Scott Gauvin is the CEO of management-consulting firm Macresco and a seasoned change agent with over 25 years experience successfully helping organizations realize their potential. Throughout his career, Scott’s focus has been on driving performance gains through organizational alignment and a progressive approach to operations strategy.

He has advised companies the world over and across a wide range of industries.

He holds a BA from the University of Massachusetts, an MBA from Boston University and is a Six Sigma Black Belt. Scott is also a frequent speaker and has presented for the American Society of Quality, The Shingo Conference, The Association for Manufacturing Excellence, Fabtech, and others.